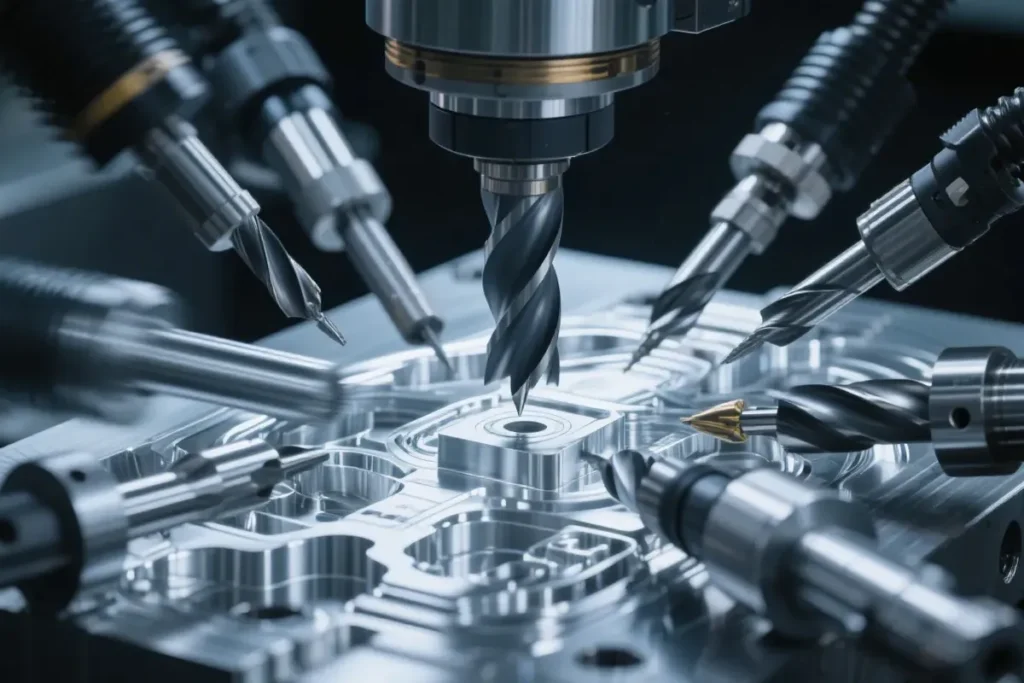

Leading CNC Tools Manufacturer

One-stop solution for CNC Tools

- Lower MOQ: Start at 10pcs for market testing

- Free Standard Samples for Performance Testing

- Fully Customizable: Tailored to your design & requirements

Who We Are

Your factory-direct source for premium precision cutting tools. Our core products include end mills, drill bits, and spiral carbide bits—backed by full OEM/ODM support, competitive pricing, and unwavering commitment to innovation & quality for global partners.

Manufacturing & Quality Excellence

- Deep Industry Expertise in Precision Cutting Tools

- 2,000+ Specialized Tool Designs – Fit for All Industries

- Advanced Technology Ensuring ±0.005mm Precision

- Quality Excellence – Defect Rate < 0.1%

Support & Cooperation Advantages

- 72-Hour Fast Response for Custom Tool Quotations

- Flexible MOQ: Start from 10pcs for Small-Batch Trials

- Global Delivery: 3-15 Days Lead Time to Major Markets

- Lifetime Technical Support Post-Purchase

What We Have

Square End Mills

Flat right-angle end (no arc transition); suitable for milling flat/step surfaces, right-angle grooves; one of the most basic milling tools.

Ball Nose Cutters

Full hemispherical end; for complex shapes (curved surfaces, cavities, arc transitions); avoids surface scratches from right-angle cutting.

Corner Radius Cutters

Arc at end corner; combines flat-milling ability and impact resistance (ball nose cutters); used for mold cavities, semi-finishing/finishing of high-strength parts.

Stainless Steel Cutters

Carbide Cutters

Alu & Copper Cutters

Why Partner With Us?

We Don’t Just Sell Tools—We Help You Win Markets

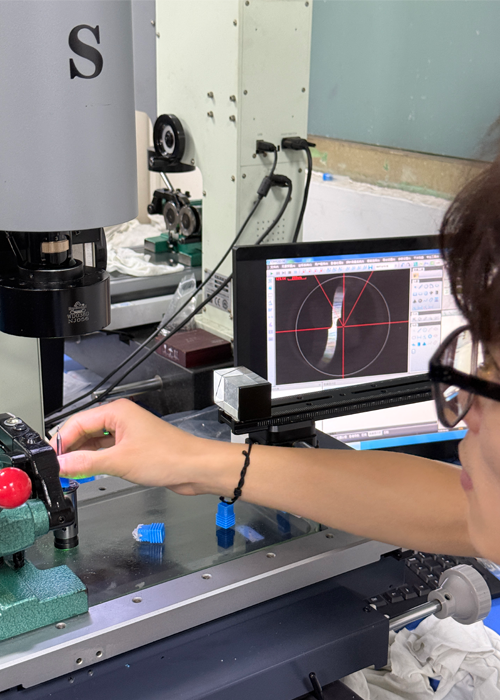

- Uncompromising Quality ControlOur 3-stage strict testing (raw material inspection → in-process checks → final performance tests) doesn’t just “ensure quality”—it cuts your defect rate to near-zero, slashes after-sales headaches, and keeps your brand reputation untarnished.

- Full OEM/ODM CapabilityFull OEM/ODM support isn’t just “customization”—we turn your ideas (unique tool specs, branded packaging, even industry-specific designs) into exclusive products. No more competing on generic tools; your niche, your rules.

- Competitive Factory-Direct PricingNo middlemen = no extra markup. Our factory-direct pricing lets you keep 15%-20% more profit per order—enough to lower your retail price, boost sales, or reinvest in growing your business.

- Reliable & Scalable ProductionOur 10,000㎡ modern facility + 24/7 supply chain doesn’t just “do production”—it handles 50,000pcs monthly orders easily, guarantees on-time delivery (even for rush jobs), and never lets your client deadlines slip.

- Dedicated Technical & Sales SupportOur technical + sales team isn’t just “support”—we reply within 24 hours (even weekends!) for inquiries, send real-time production updates, and help troubleshoot tool use post-purchase. Your partnership, no hassle.

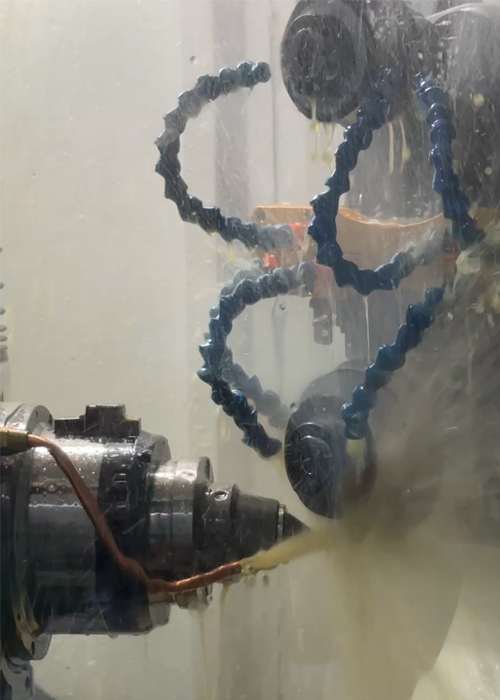

Our Manufacturing Facility

Our factory isn’t just a production site—it’s the backbone of your reliable tool supply. See how we combine advanced tech, strict quality control, and flexible lines to meet your needs.

Precision Machining Area

Strict Quality Inspection Zone

Raw Material & Finished Goods Storage

Custom Production Line

Certified for Quality

We hold international certifications to ensure our production, quality control, and service meet global standards.

1. ISO 9001: Certified Quality Management

2. E-Mark: European Road Safety Approval

3. DOT Compliance: North American Market Ready

4. CE Marking: European Conformity & Safety

5. RoHS Compliance: Free of Hazardous Substances

6. IP67/IP68 Rated: Verified Weatherproof Durability

Trusted by Clients Worldwide

Ready to Elevate Your Machining with Reliable CNC Tools?

Backed by ISO 9001 certification, 2,000+ tool designs, and 100+ global client reviews—we’re here to turn your needs into solutions.