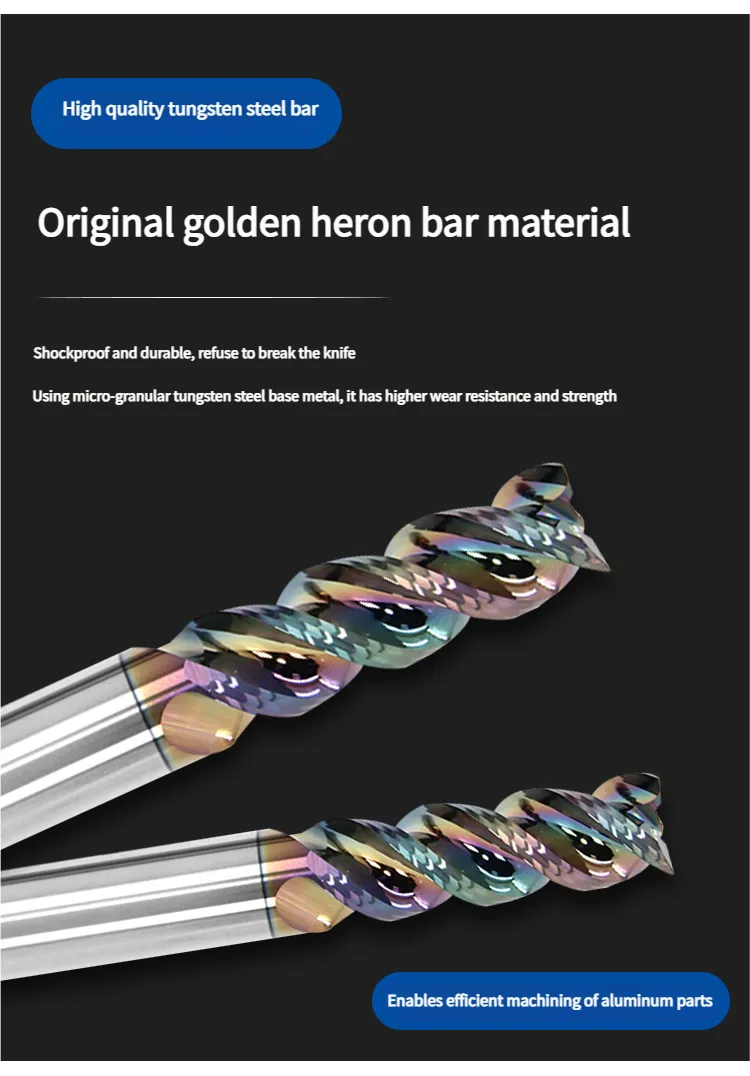

Fancy Dark Coating = No Stick

Mirror-Like Finish on Aluminum

U-Flute for Chip-Free Finish

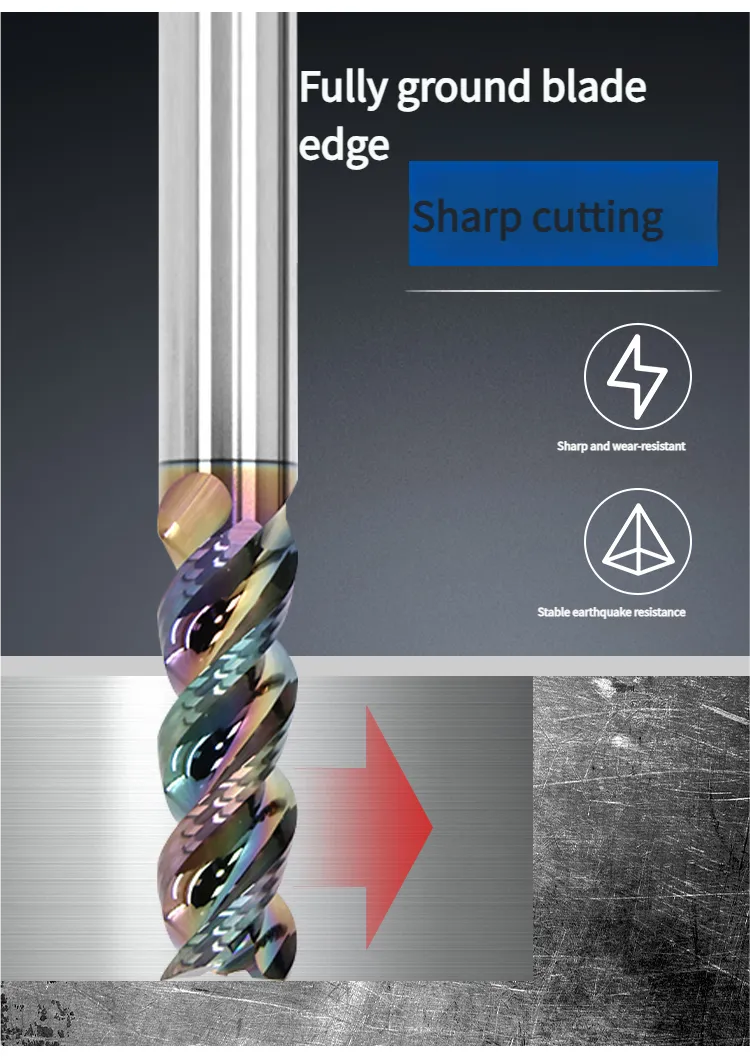

Aluminum-Optimized Sharp Edge

Longer Life for Finishing

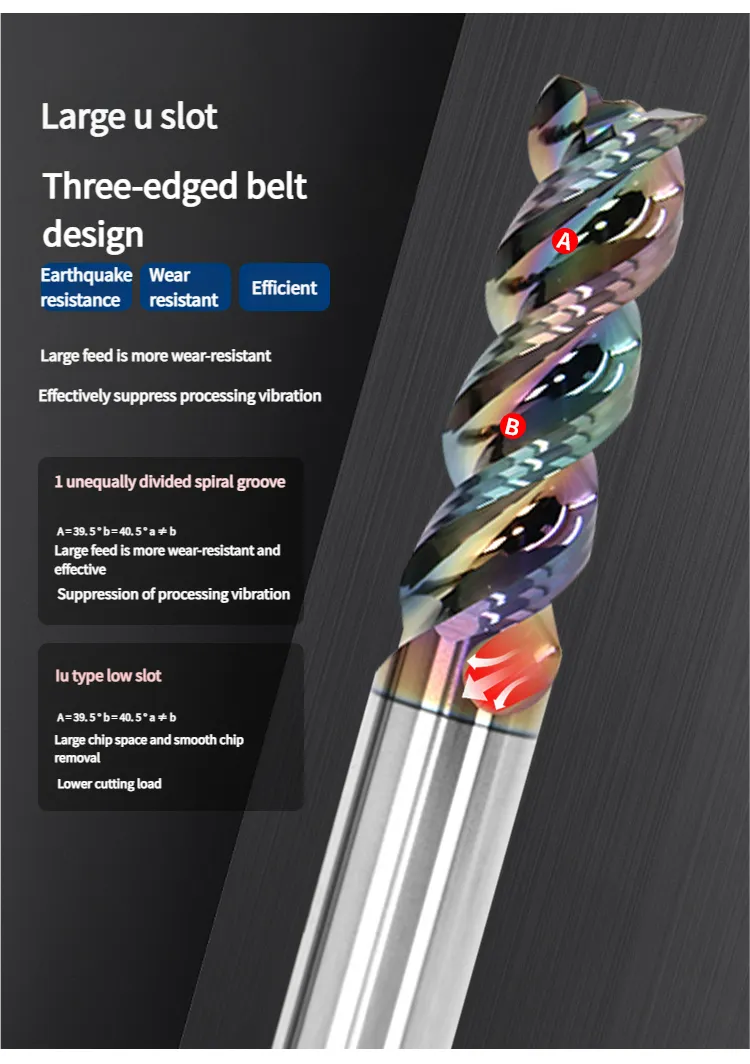

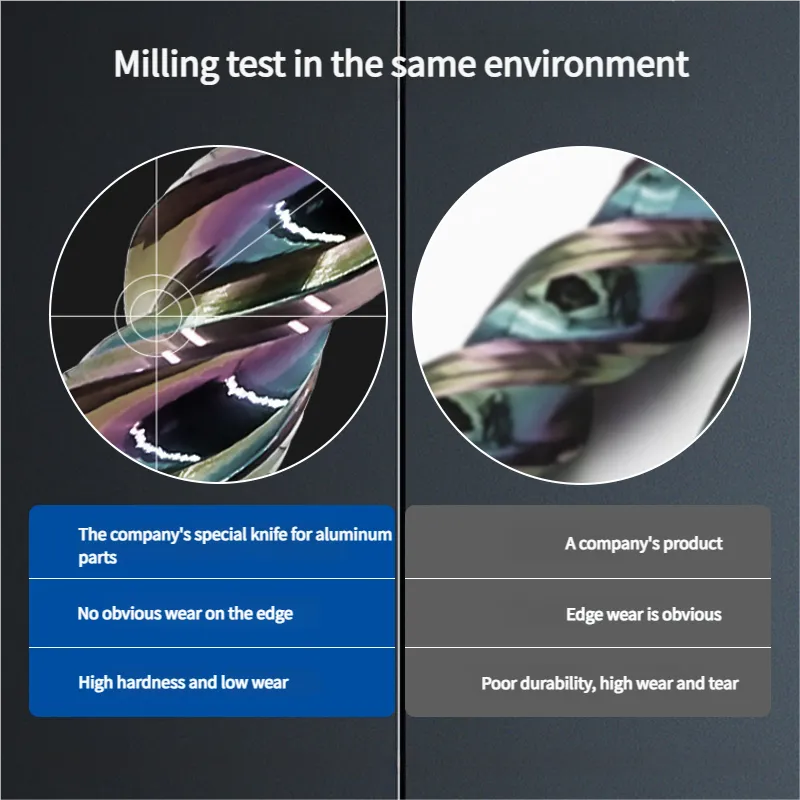

Designed exclusively to solve the core challenge of “material stickiness” in machining non-ferrous metals like aluminum and copper, this is a high-end tool for finish machining and semi-finish machining. Its core goals are to achieve anti-adhesion (no built-up edge), mirror-like surface finish, while ensuring machining stability and long tool life.

Fancy Dark (Special PVD Coating)

U-Flute for Al & Cu

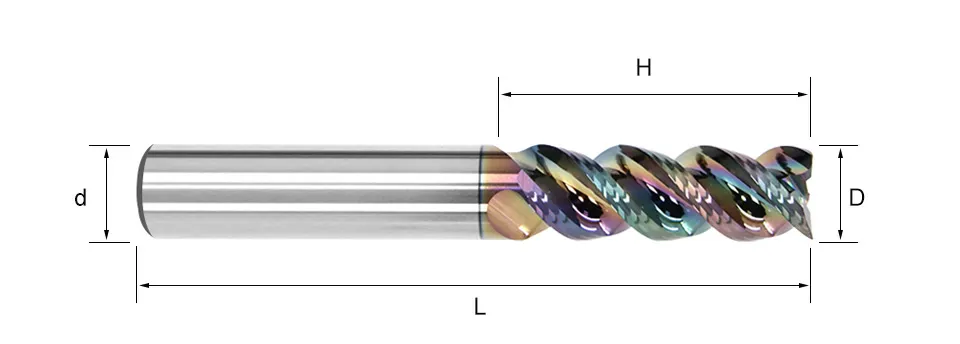

Flat-End Mill Structure

| Product | Model | Basic Sizes (mm) | Flute | HRC | |||

| d(Shank ∅Dia ) | L(Overall Length) | D(Flute ∅Dia ) | H(Flute Length) | ||||

| Composite Coated Flat End Mill For Alu. &Copper |

D6 | 6 | 50 | 6 | 15 | 4F | 50/60/65 |

| D8 | 8 | 60 | 8 | 20 | 4F | 50/60/65 | |

| D10 | 10 | 75 | 10 | 25 | 4f | 50/60/65 | |

Your trusted partner for all home repair needs. Quality service, reliable results—just a click away.

We will contact you within 24 hours, please pay attention to the email with the suffix “@yxcnccutter.com”.