Flat End Mill – GT Series For High Hardness Steel

Crafted with ultra-fine grain cemented carbide and imported target coating, the GT Series delivers exceptional high-temperature resistance and wear resistance. The smooth-coated surface minimizes cutting resistance, ensuring stable performance even under intense machining conditions.

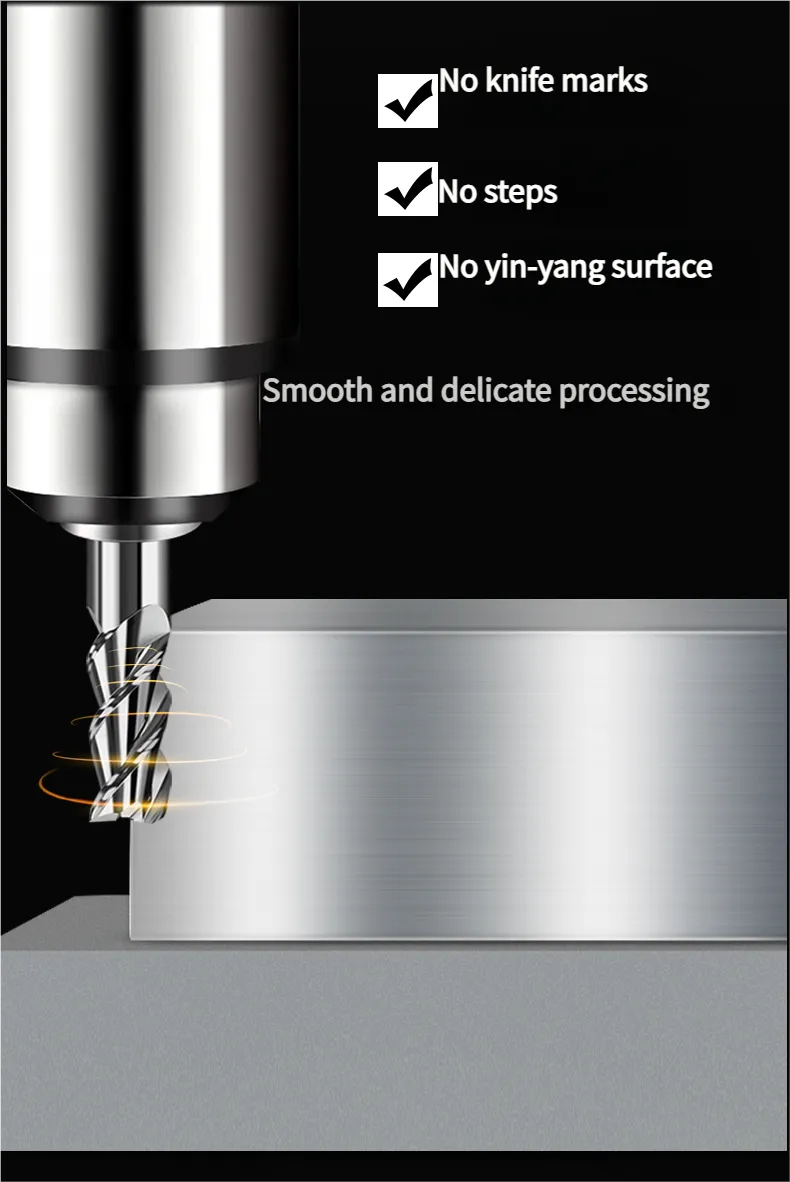

- Core Functions: 2D contour cutting, flat surface machining, grooving;

- Key Features: High edge strength, excellent for machining 90° vertical sidewalls and corner cleaning;

- Analogy: Similar to a painter’s brush, it efficiently handles large-area flat surfaces with sharp, clear edges.

- High hardness & large cutting force: Requires tools with ultra-high strength and toughness to prevent edge chipping and breakage;

- High cutting temperature: High-speed cutting generates massive heat, demanding tools (body & coating) with excellent heat resistance and hot hardness;

- High wear resistance requirement: Carbide particles in steel severely abrade tools, requiring extreme wear resistance;

- Difficult chip breaking: Tends to form long, continuous chips that wrap around the tool, endangering both the workpiece and tool.

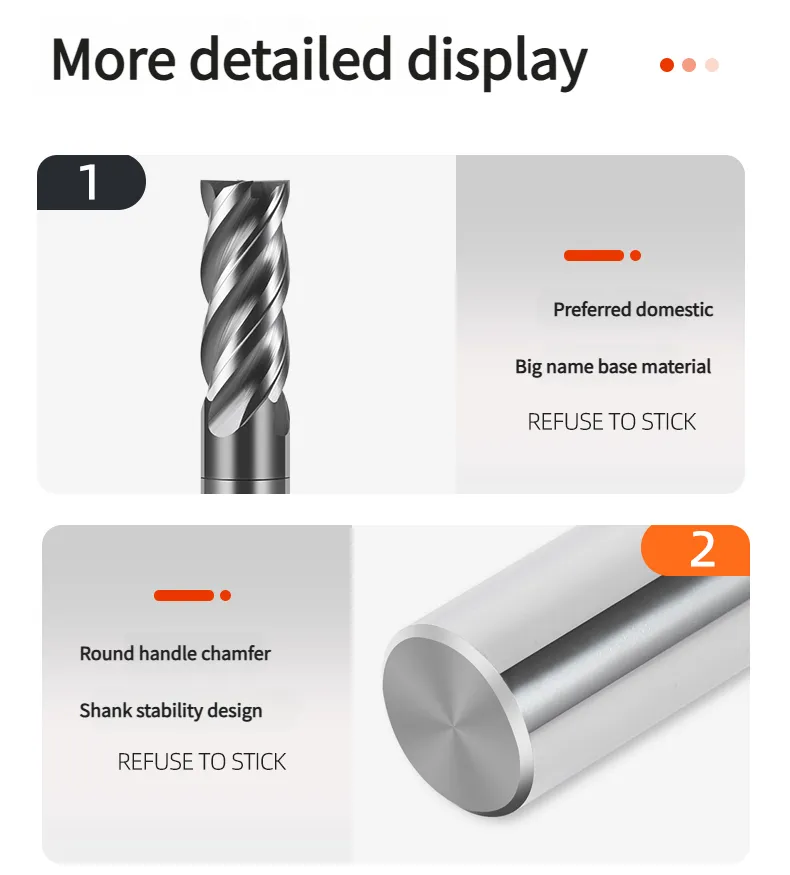

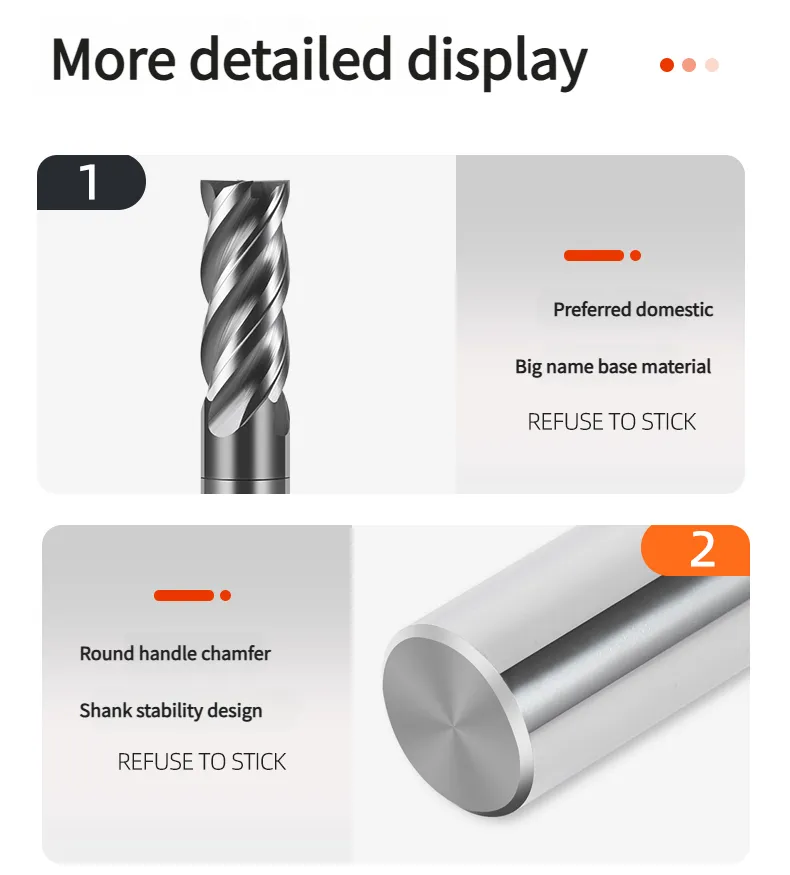

- Tough Tool Body: Made of high-toughness, high-strength cemented carbide. Suitable for heavy cutting with large depth of cut and high feed rate; resists impact and vibration when machining materials with inclusions or uneven hardness, avoiding edge chipping/breakage.

- Advanced Wear-Resistant Coating (Core Tech):

- Main Materials: TiAlN, AlTiN-based coatings, or composite coatings (e.g., TiSiN, AlCrN) with added Si/Cr;

- Key Advantages: High hardness (for wear resistance), stable performance at up to 900°C, oxidation resistance, and thermal barrier effect (isolates cutting heat to protect the tool body).

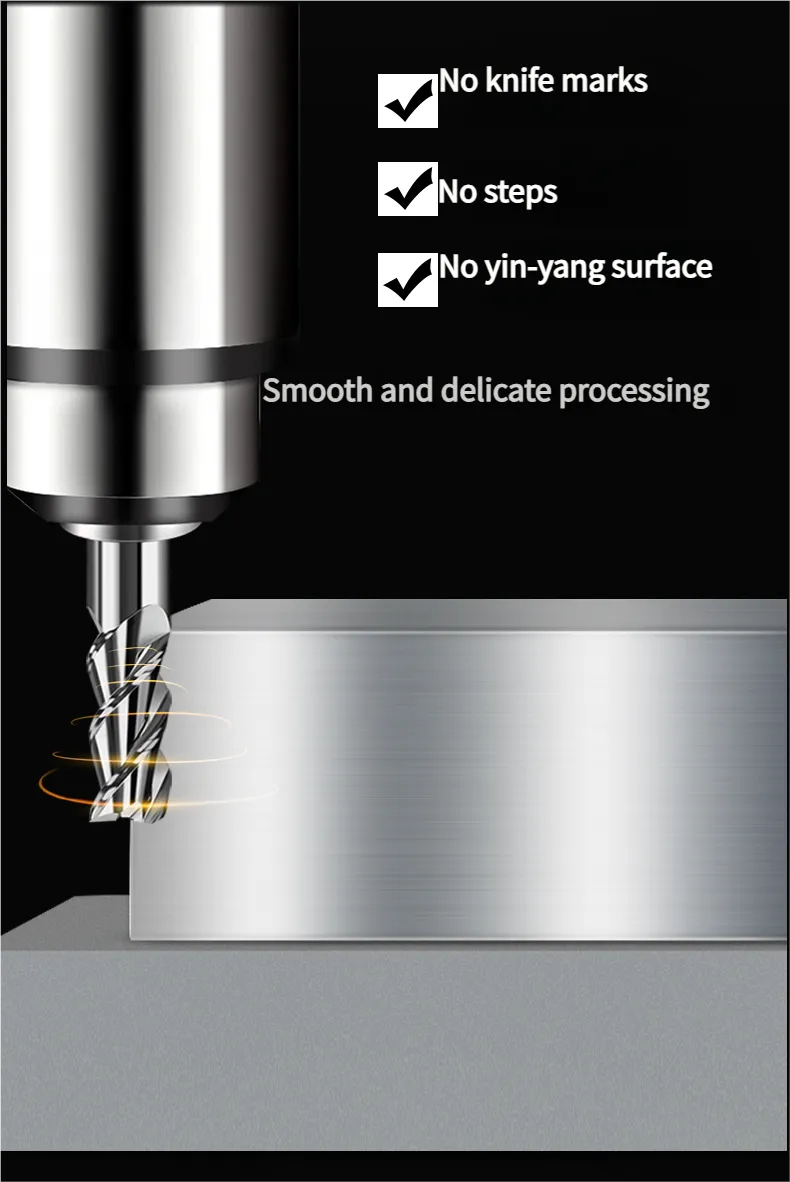

- Optimized Flute & Geometry Design:

- Design Focus: Prioritizes strength and chip evacuation (different from “large & sharp” aluminum-specific tools);

- Key Traits: Small rake angle + thick core (enhances edge strength), micro-passivated/reinforced edge (prevents micro-chipping), optimized chip flutes (ensures chip curling and smooth discharge).

- Multiple Flute Count Options:

- 4+ flutes: For finish/semi-finish machining; offers high stability and superior surface quality;

- 2-3 flutes: For roughing/deep cavity machining; large chip capacity ensures smooth chip evacuation.

- Mold Manufacturing: Roughing, semi-finishing, and finishing of mold components (cores, cavities, sliders) made of mold steel (e.g., P20, H13, S136, NAK80);

- Aerospace: Machining of high-strength alloy steel and titanium alloy structural parts;

- Automotive Industry: Milling of alloy steel parts (engine components, gearbox gear blanks);

- General Machinery: Machining of structural steel parts (e.g., 45# steel, 40Cr).

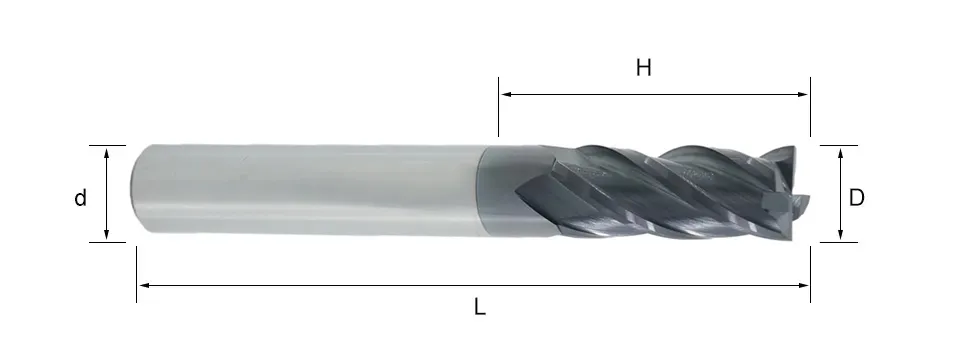

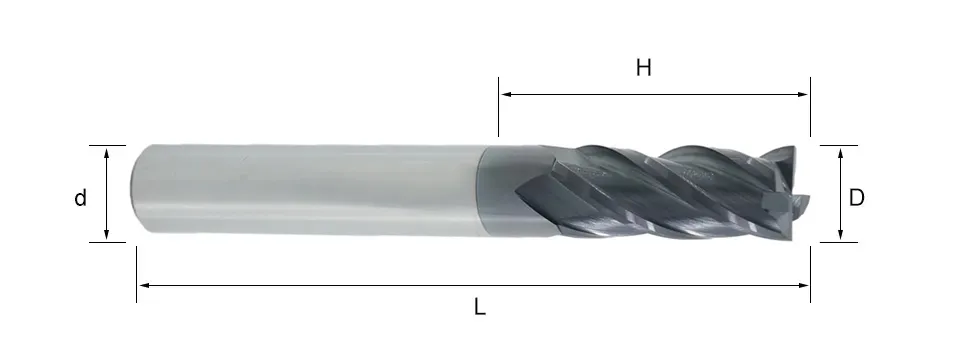

Common Product Data

| Product |

Model |

Basic Sizes (mm) |

Flute |

HRC |

| d(Shank ∅Dia) |

L(Overall Length) |

D(Fluete ∅Dia) |

H(Flute Length) |

Flat End Mill

For High Hardness Steel |

D6 |

6 |

50 |

6 |

15 |

4F |

50/60/65 |

| D8 |

8 |

60 |

8 |

20 |

4F |

50/60/65 |

| D10 |

10 |

75 |

10 |

25 |

4F |

50/60/65 |

Product information