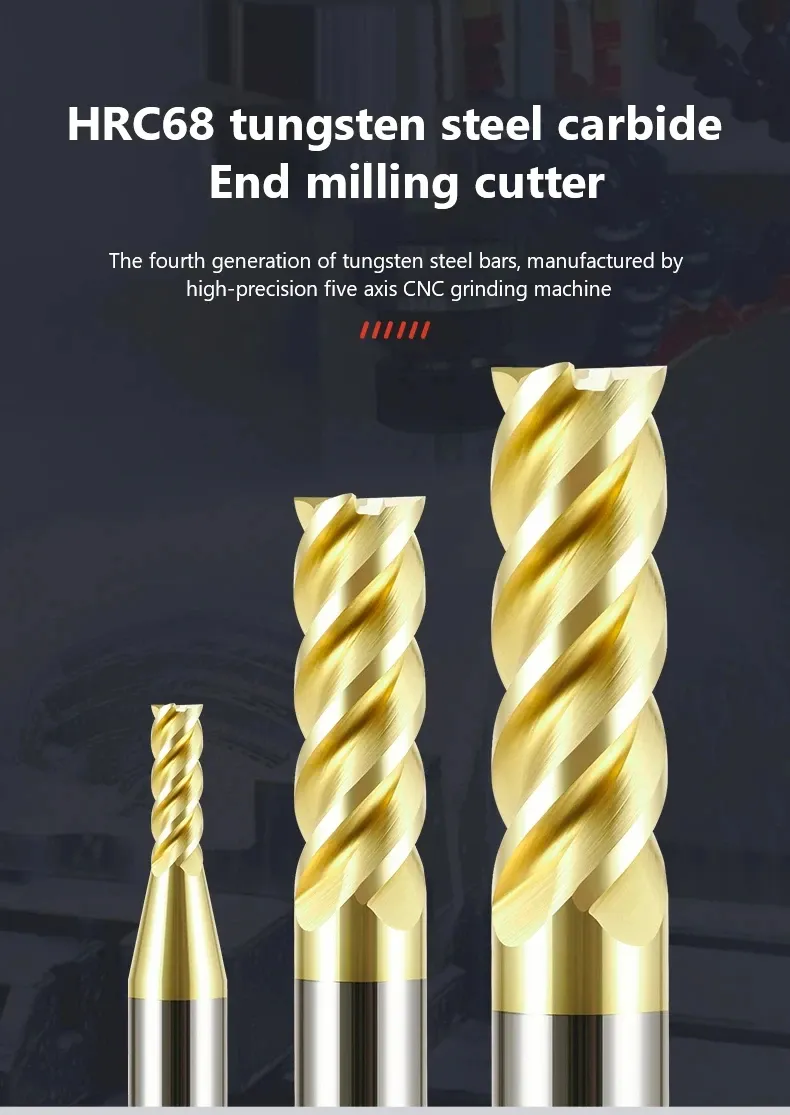

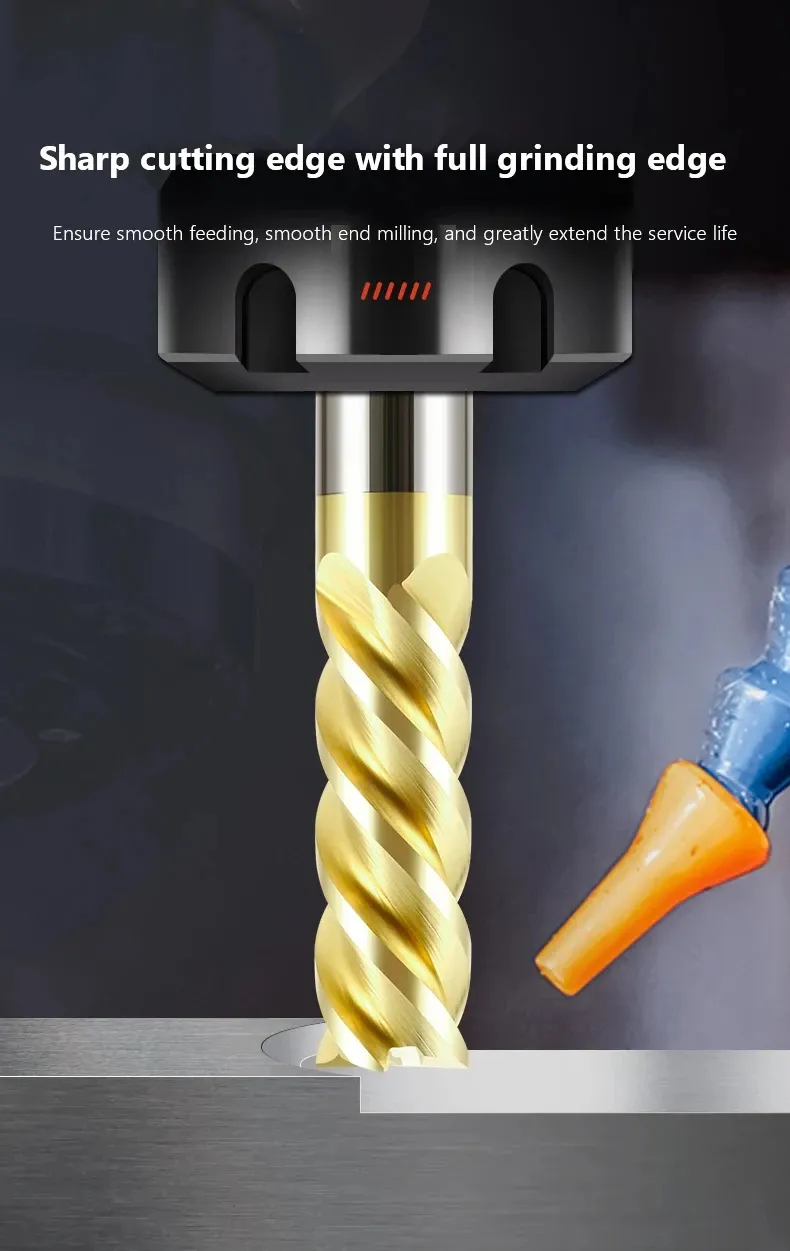

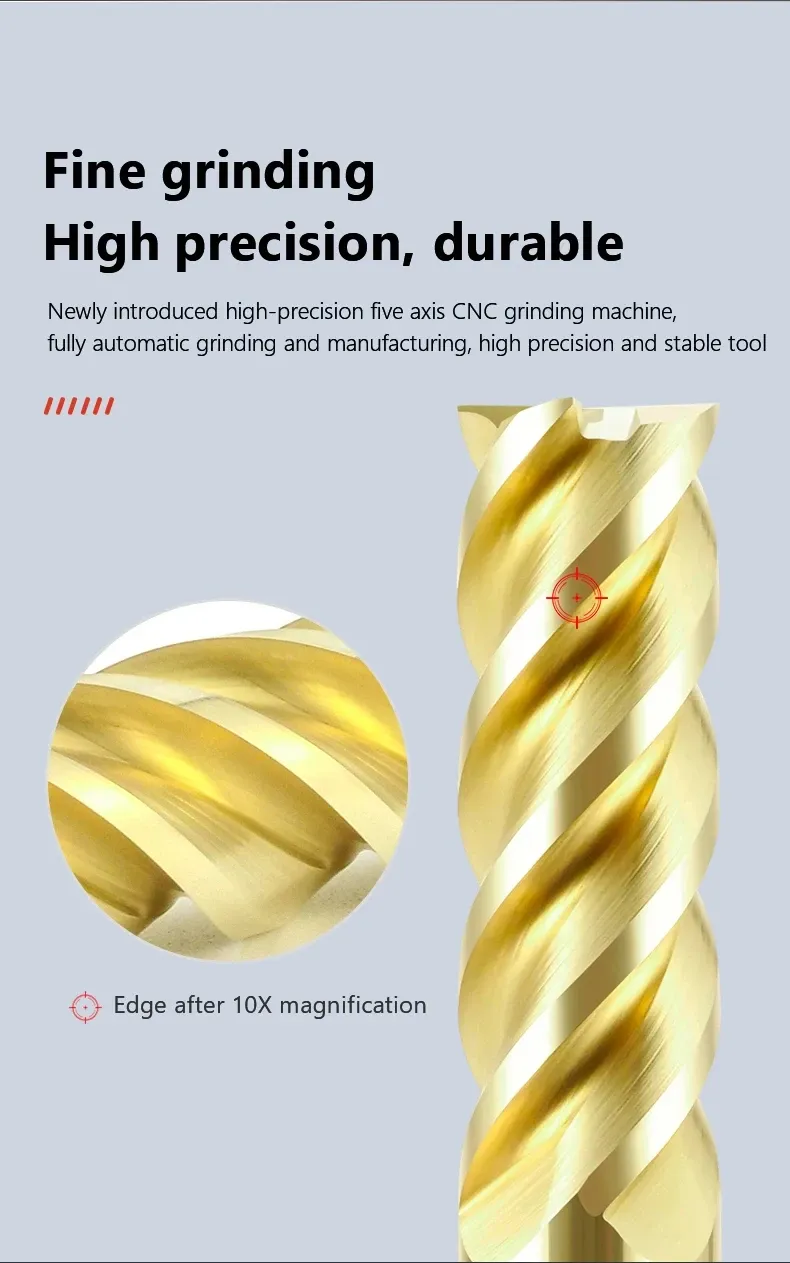

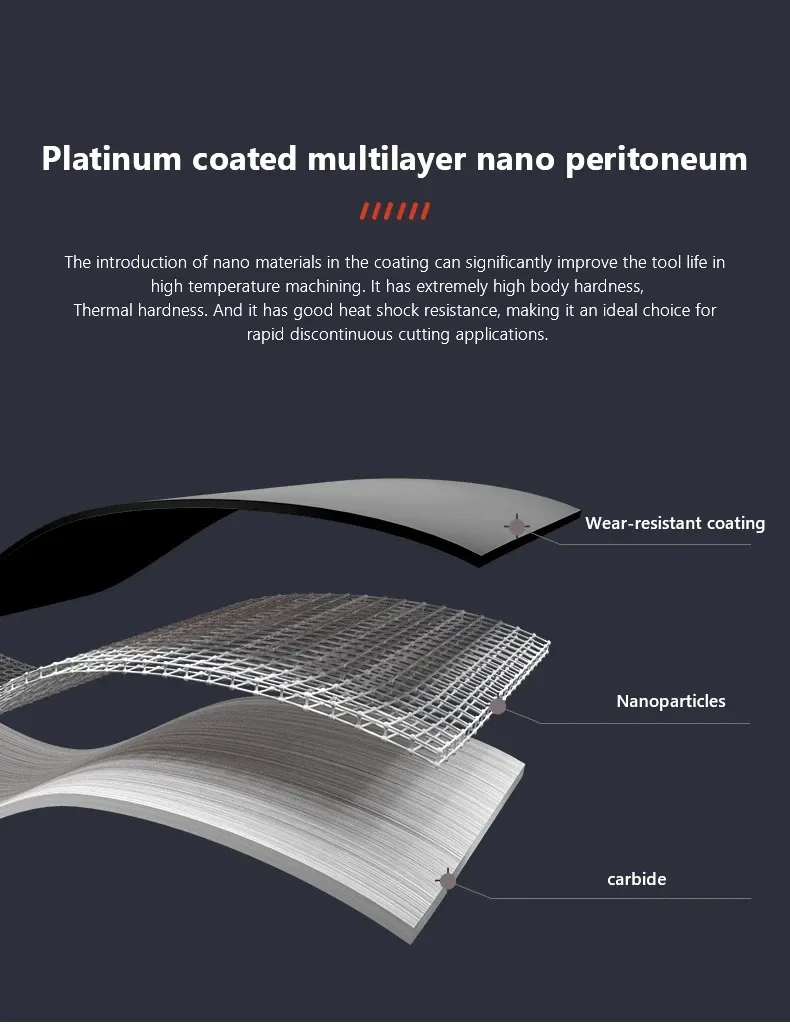

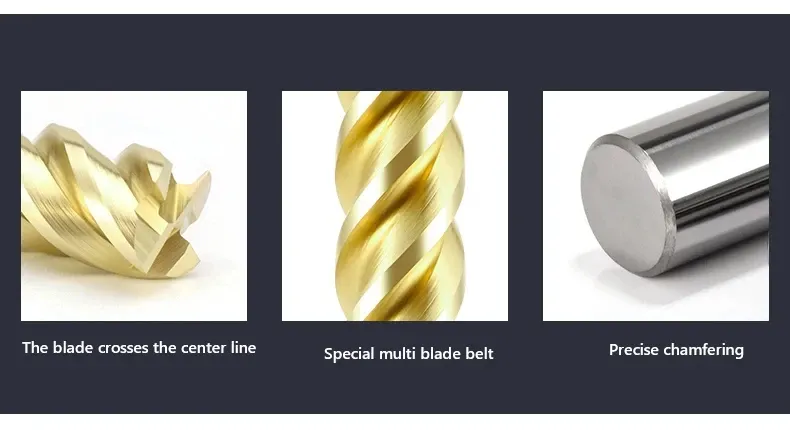

The GTU Titanium Series is a top-tier professional tool. With heat control as the core, it solves titanium machining challenges through a tough tool body, special coating and optimized geometric design. It provides a key guarantee for safe, efficient and high-quality titanium machining.

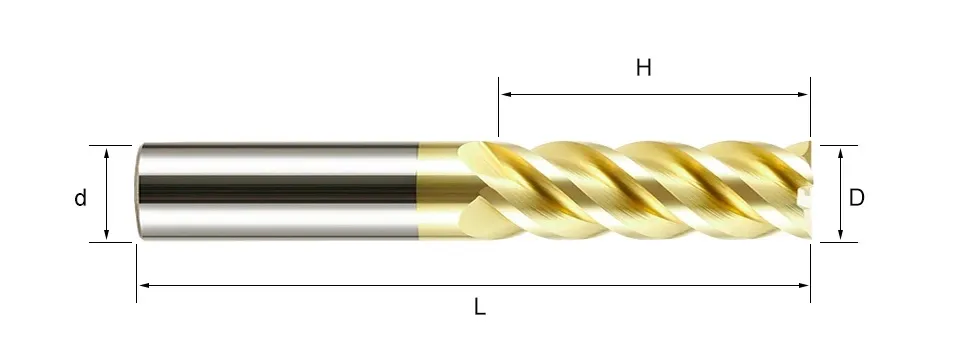

| Product | Model | Basic Sizes (mm) | Flute | HRC | |||

| d(Shank ∅Dia) | L(Overall Length) | D(Fluete ∅Dia) | H(Flute Length) | ||||

| Flat End Mill For Titanium |

D6 | 6 | 50 | 6 | 15 | 4F | 50/60/65 |

| D8 | 8 | 60 | 8 | 20 | 4F | 50/60/65 | |

| D10 | 10 | 75 | 10 | 25 | 4F | 50/60/65 | |

Your trusted partner for all home repair needs. Quality service, reliable results—just a click away.

We will contact you within 24 hours, please pay attention to the email with the suffix “@yxcnccutter.com”.