Meta Description: Confused between ball nose and corner radius end mills? This in-depth guide breaks down their key differences in geometry, applications, and performance to help you master CNC tool selection.

Introduction

In the world of CNC milling, selecting the right tool for the job is critical for success. Among the various types of end mills, Ball Nose and Corner Radius end mills are often confused by beginners and even experienced machinists. While they may look similar at a glance, these two tools serve fundamentally different purposes.

Choosing the wrong one can lead to inefficient machining, poor surface finish, and premature tool failure. This guide will demystify these two tool types, providing a clear comparison of their geometries, strengths, and ideal applications to help you make the perfect choice for your next project.

1. Core Definitions & Geometry

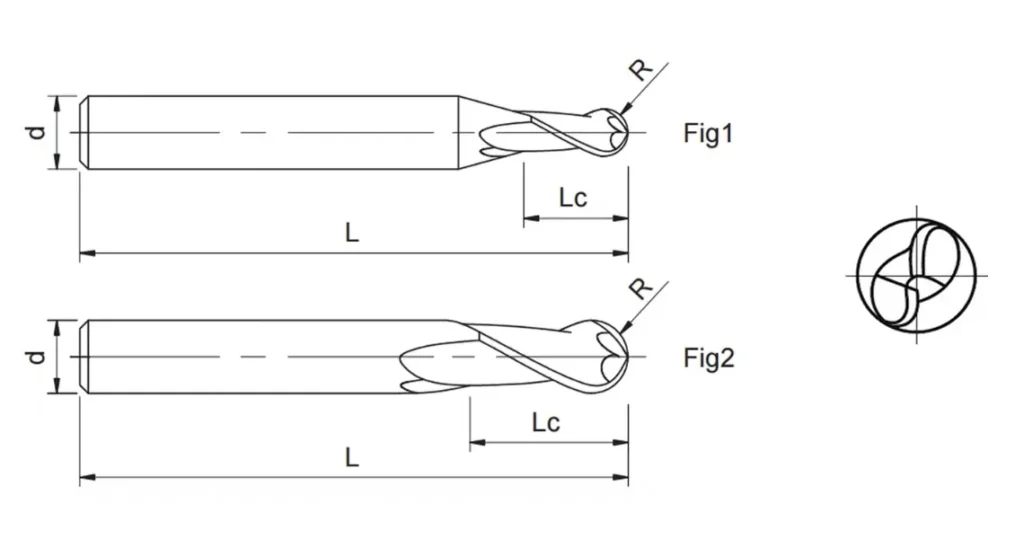

Ball Nose End Mills

A Ball Nose End Mill has a hemispherical tip, just like a ball. Its cutting edges form a continuous radius from one side of the tool to the other.

Key Characteristics:

- The tip radius is always equal to half the tool’s diameter.

- The cutting speed varies along the radius: it’s highest at the outer diameter and theoretically zero at the very center. This means the center point tends to rub and squeeze the material rather than shear it, which can lead to heat buildup, work hardening, and poor chip evacuation.

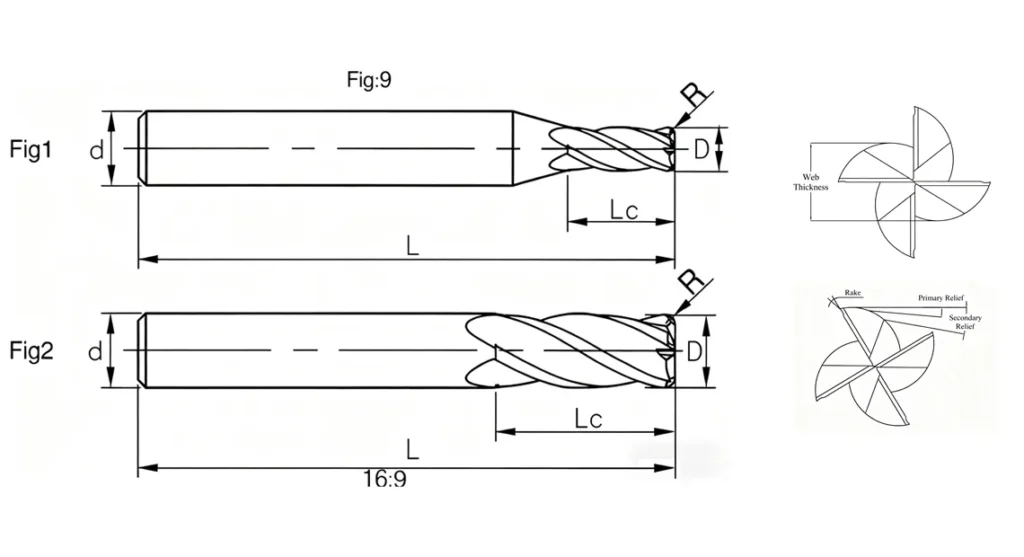

Corner Radius End Mills

A Corner Radius End Mill, also known as a bull nose or rounded corner end mill, features a flat bottom (face) with defined radial corners. Think of it as a square end mill whose sharp, fragile corners have been strengthened with a specific radius.

Key Characteristics:

- Has a flat end face and a defined corner radius.

- It combines the roughing efficiency of a square end mill with the durability and finishing capability needed for shallow contours. The radius eliminates the stress concentration point, drastically reducing the risk of corner chipping.

2. Head-to-Head Comparison: The Core Differences

| Feature | Ball Nose End Mill | Corner Radius End Mill |

| Tip Geometry | Full hemisphere | Flat bottom with corner radii |

| Corner Radius | Fixed at 50% of tool diameter | Variable (typically <50% of tool diameter) |

| Primary Application | 3D contouring, sculpting, mold making | Shoulder milling, pocketing, 2.5D profiling |

| Surface Finish | Excellent on complex, deep 3D surfaces | Superior on flat surfaces and shallow contours |

| Tool Strength | Weaker tip, prone to deflection and wear at the center | Stronger corners, better shock resistance, more rigid |

| Machining Efficiency | Excellent for 3D finishing, poor for roughing | Highly efficient for both roughing and semi-finishing |

3. How to Choose: Application Deep Dive

When to Use a Ball Nose End Mill

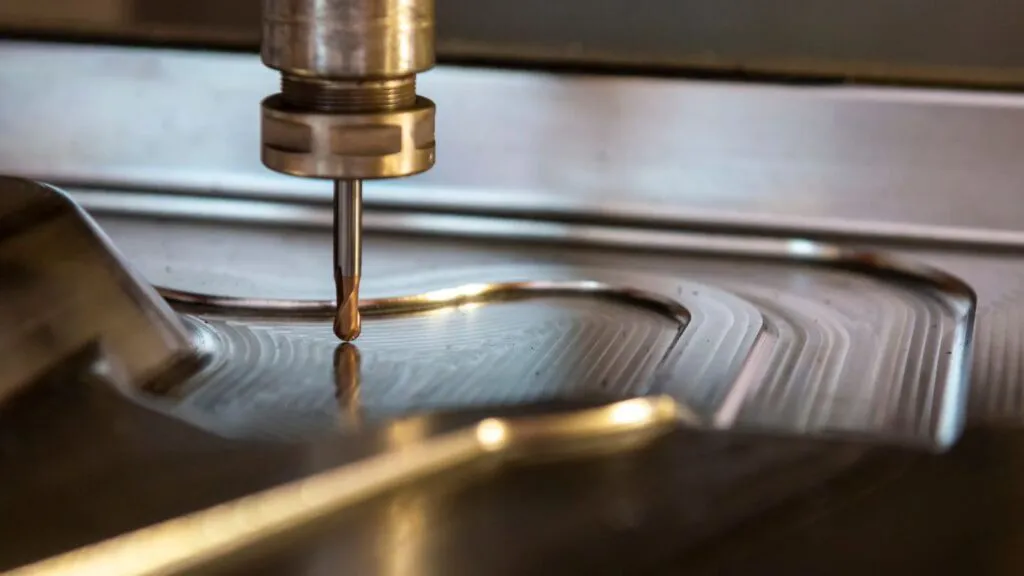

The Ball Nose End Mill is the undisputed champion of 3D contour machining. Its continuous spherical geometry allows it to smoothly follow complex, organic surfaces that would be impossible with other tools.

Ideal Use Cases:

- Mold & Die Making: Finishing complex cavities for injection molds or die casts.

- Aerospace Components: Machining turbine blades, impellers, and other complex engine parts.

- Artistic Engraving & Sculpting: Creating detailed 3D reliefs and patterns.

- Medical Implants: Producing the curved surfaces of artificial joints (knees, hips).

According to the Sandvik Coromant milling handbook, using trochoidal milling or Z-level contouring strategies is key to maximizing efficiency and tool life with ball nose end mills.

When to Use a Corner Radius End Mill

The Corner Radius End Mill is a versatile all-rounder. It blends the roughing power of a square end mill with the durability and finishing capabilities needed for many common tasks. The radius eliminates the weak sharp corner, distributing stress and preventing chipping.

Ideal Use Cases:

- Pocketing & Roughing: The radius drastically increases tool life by preventing corner chipping under high stress.

- Shoulder Milling: Capable of producing square shoulders with a root radius in a single operation.

- 2.5-Axis Profiling: Perfect for parts requiring smooth external fillets or internal radii.

- Hard Material Machining: The stronger corner makes it more suitable for milling hardened steels, titanium, and other tough alloys.

As emphasized in the McMaster-Carr tooling catalog ,corner radius end mills are a fundamental category for improving tool life and surface finish on a wide range of materials.

How to Choose the Radius Size:

The radius is typically selected based on the internal corner requirement of your part design. A common practice is to select a tool with a radius slightly smaller (e.g., 0.5mm) than the part’s fillet to ensure the tool can fully clean out the corner.

4. Frequently Asked Questions (FAQ)

Q1: Can I use a ball nose end mill for roughing?

It is generally not recommended for heavy roughing. The poor cutting conditions at the tool center make it inefficient and prone to rapid wear. For roughing 3D shapes, a ball nose tool paired with a trochoidal toolpath is acceptable, but a corner radius end mill is typically a more robust and efficient choice for the bulk of material removal.

Q2: How do I choose the corner radius size?

The radius is typically selected based on the internal corner requirement of your part design. A common practice is to select a tool with a radius slightly smaller than the part’s fillet to ensure proper clean-out.

Q3: Which tool is more rigid and stable?

The Corner Radius End Mill is significantly more rigid. Its shorter cutting edges and robust corner geometry allow it to withstand higher lateral cutting forces with less vibration and deflection.

Conclusion

The decision between a ball nose and a corner radius end mill ultimately comes down to the geometry of your part.

- For mastering intricate 3D contours and complex surface finishing, the Ball Nose End Mill is your go-to tool.

- For a versatile workhorse that excels at roughing, shoulder milling, and 2.5D profiling with enhanced durability, the Corner Radius End Mill is the clear winner.

Understanding their fundamental differences and applying them correctly will directly translate to higher machining efficiency, superior part quality, and longer tool life. On your next CNC project, let the geometry of your part guide your choice, and you’ll be sure to achieve optimal results.