DLC Coating for No Stick

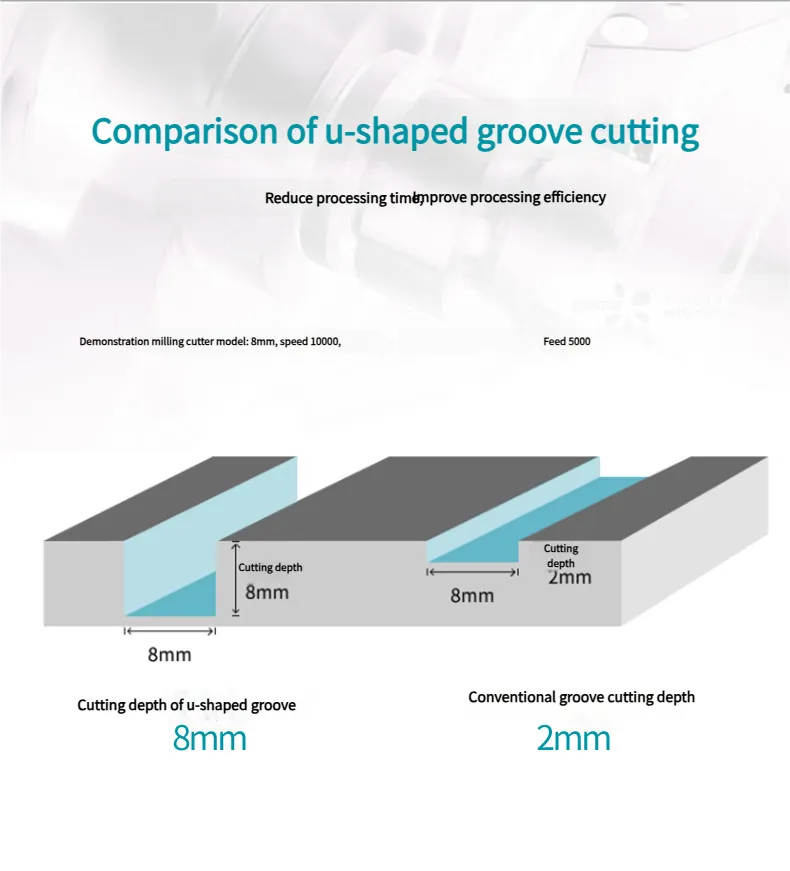

U-Flute for Super Fast Chip Evac

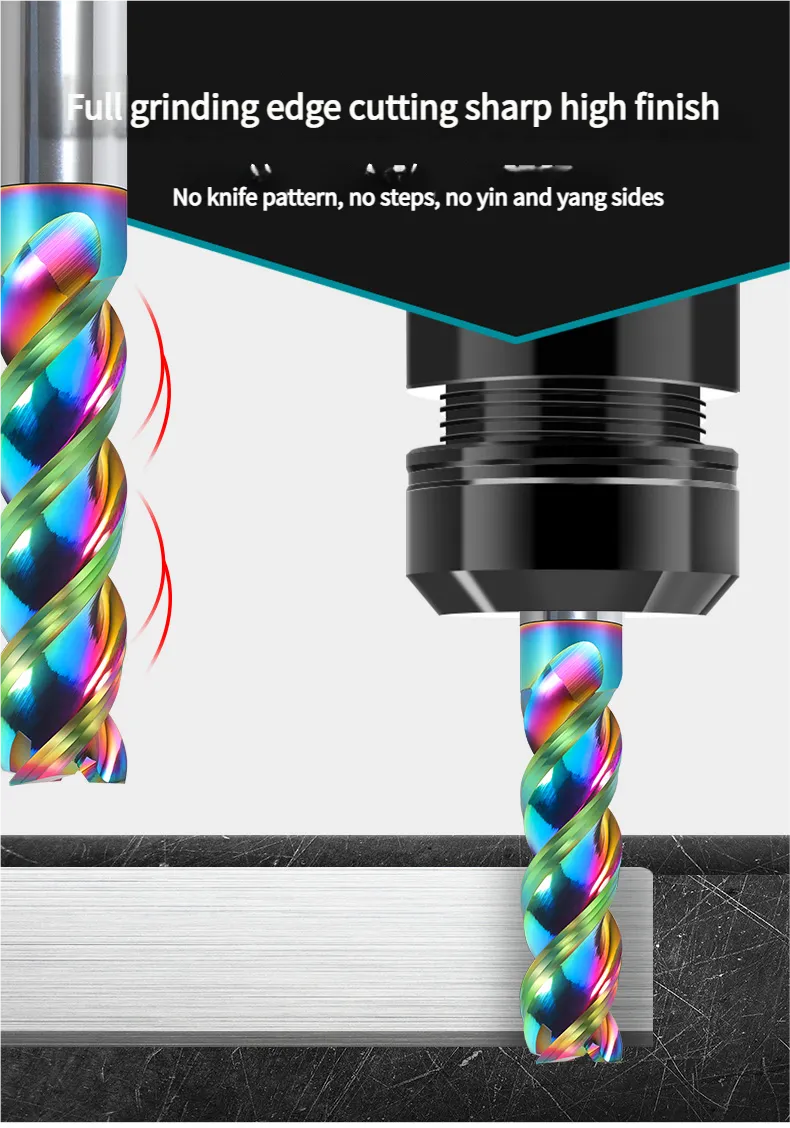

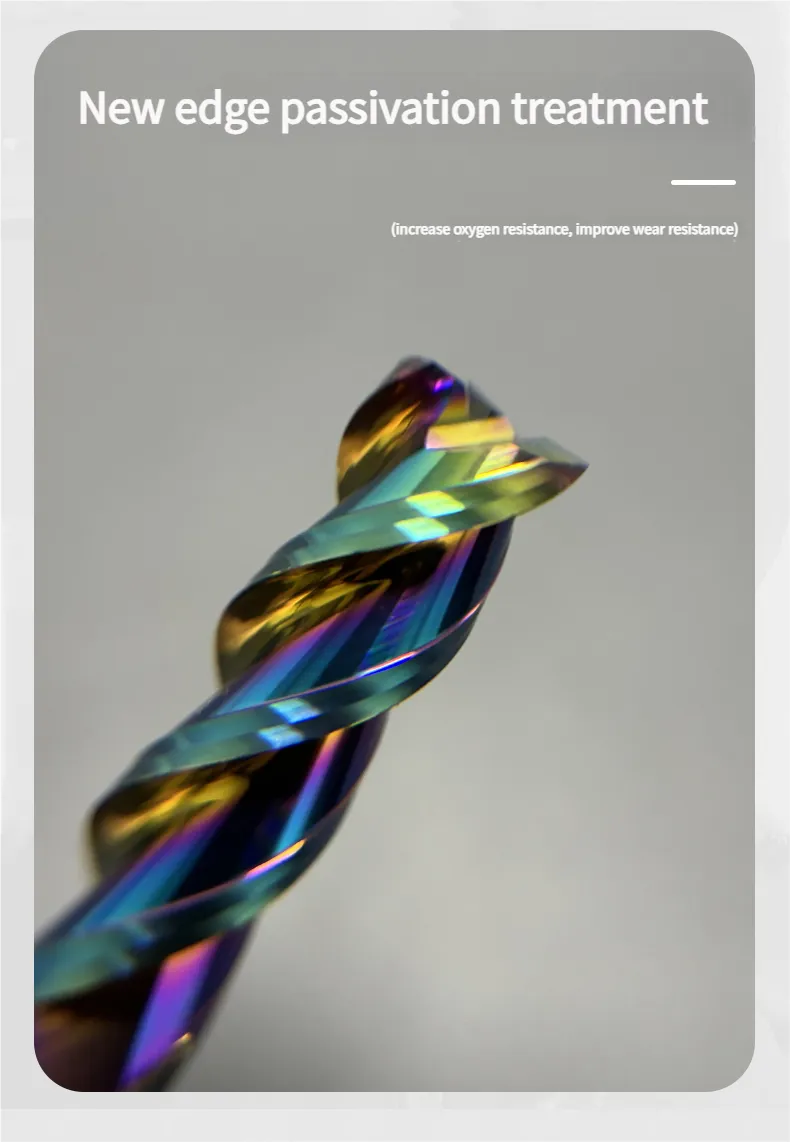

Sharp Edge for Mirror Finish

Aluminum-Specific Design

This DLC-U Flute Flat-End Mill is a professional tool specifically designed for efficient, high-quality milling of aluminum, copper, and other soft, sticky non-ferrous metals. All designs revolve around one core goal: achieving extreme chip evacuation and preventing material adhesion under ultra-high cutting parameters, ultimately ensuring excellent machining surfaces and extended tool life.

U Flute (Large Chip Pocket Design)

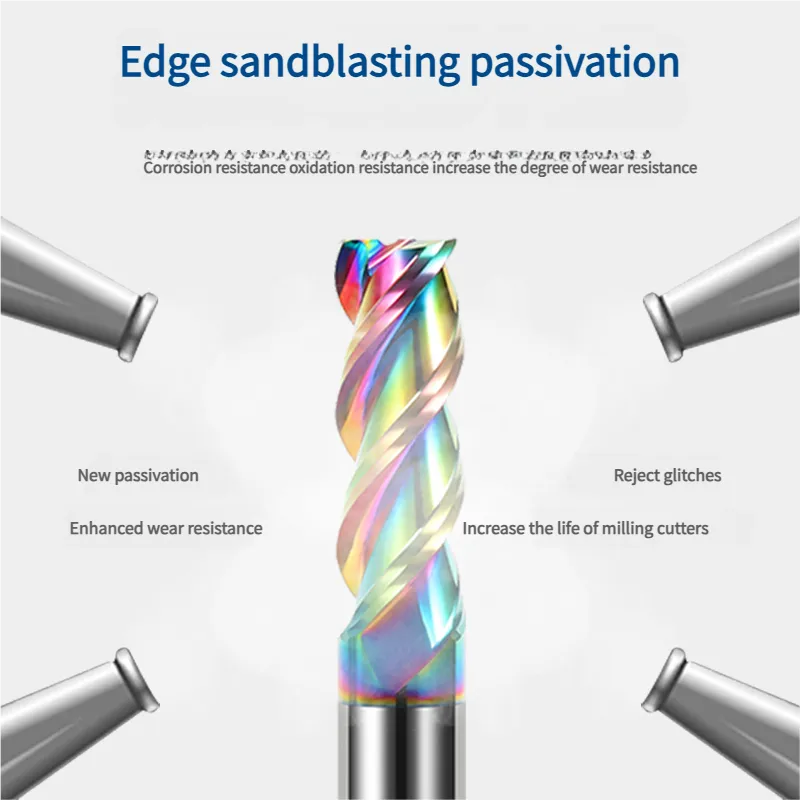

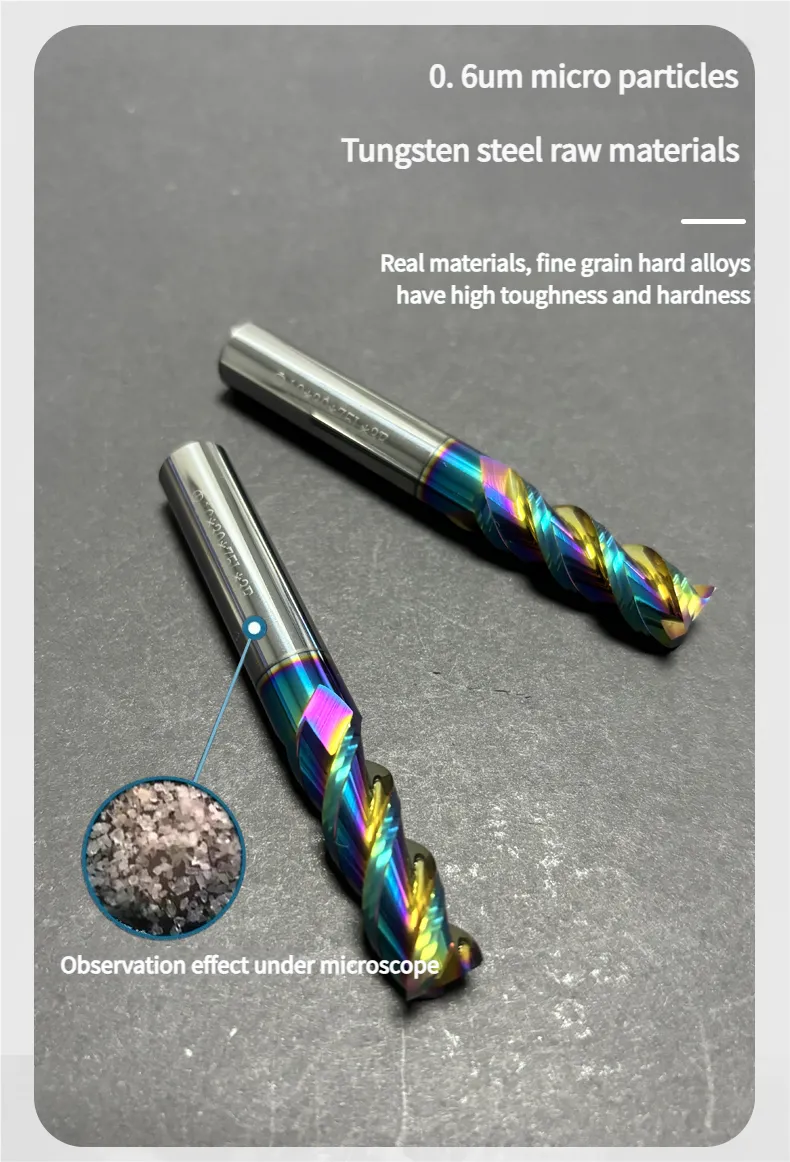

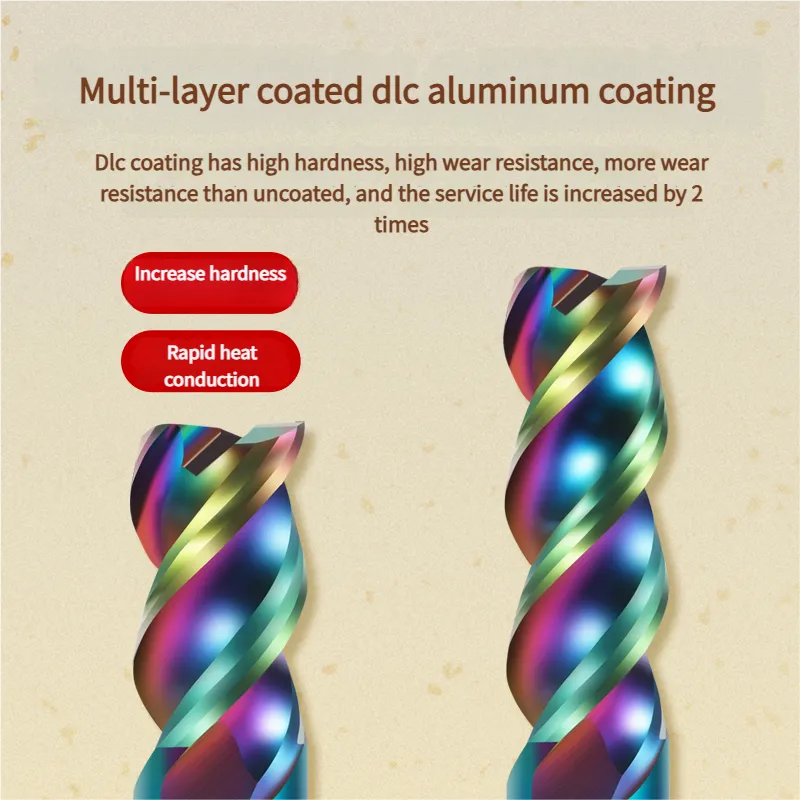

DLC (Diamond-Like Carbon Coating)

Flat-End Mill Structure

For Aluminum & Copper (Material & Edge Optimization)

Precision Mold Manufacturing

Aerospace Industry

Consumer Electronics Industry

Precision Parts Machining

Specialized Tool

Machine Requirements

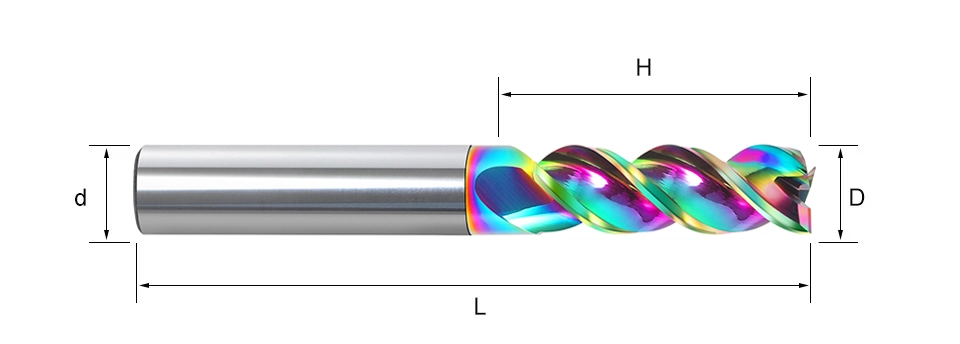

| Product | Model | Basic Sizes (mm) | Flute | HRC | |||

| d(Shank ∅Dia ) | L(Overall Length) | H(Flute ∅Dia ) | H(Flute Length) | ||||

| Coated Flat End Mill For Alu. &Copper |

D6 | 6 | 50 | 6 | 15 | 4F | 50/60/65 |

| D8 | 8 | 60 | 8 | 20 | 4F | 50/60/65 | |

| D10 | 10 | 75 | 10 | 25 | 4f | 50/60/65 | |

Your trusted partner for all home repair needs. Quality service, reliable results—just a click away.

We will contact you within 24 hours, please pay attention to the email with the suffix “@yxcnccutter.com”.